Camera modules play a crucial role in capturing and delivering high-quality images and videos in the realm of technology and innovation. A camera module’s journey from the factory to its final destination is crucial, whether it will be used for industrial inspections, security systems, or entertainment devices. The skillful packaging of camera modules for transport is a crucial but it’s a often overlooked part of this process in the realm of camera manufacturing. This article will discuss the factors that must be taken into account when packing camera modules to ensure they arrive at their destination unscratched.

Protecting the Heart of Innovation

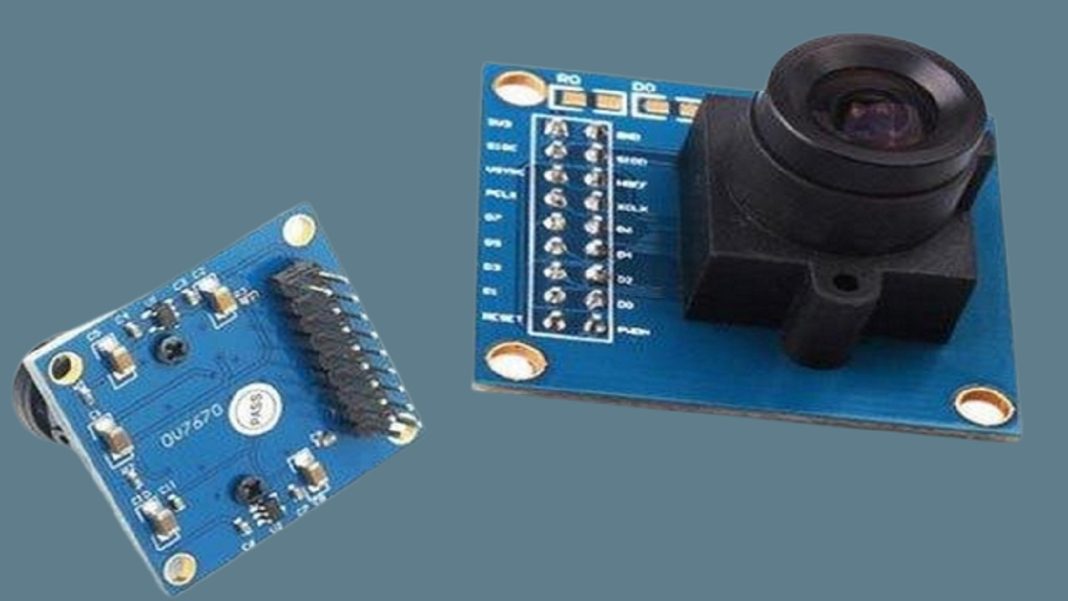

Sensors, lenses, printed circuit boards, and other delicate parts make up the camera module’s complex design. Together, these parts form the beating heart of many cutting-edge programs, allowing for efficient image capture and processing. It is crucial that this complex equipment be kept safe during transport so that it can be put to use immediately upon arrival. The procedure is as follows:

Safe Containers

Choosing suitable housings is the first step in packing camera modules. The camera modules are stored in a safe and cushioned environment made of foam, bubble wrap, or specially-made boxes. These cases are constructed to dampen vibrations and shocks, protecting their contents from harm on the road.

Static-Prevention Techniques

Sensitive electronic components can be damaged by electrostatic discharge (ESD). Anti-static packaging and procedures are crucial for reducing this risk. The camera modules are protected from static electricity by using anti-static bags, foams, and handling procedures

Sealing the Package

The camera modules must be sealed in packaging to prevent damage from dust, moisture, and humidity. To prevent the camera modules from being damaged by moisture or dust, they are stored in hermetic containers. When shipping internationally, where exposure to varying climates is a potential issue, this precaution becomes all the more crucial.

Layered Approach

Layering is key to mastering the art of camera module packing. To prevent unwanted movement or wear from rubbing, the workers individually wrap and cushion each part. Protecting fragile components like lenses and sensors in this way is essential.

Labeling and Recordkeeping

An often overlooked but crucial part of packing is labeling and documentation. Packages containing camera modules should be clearly labeled with handling instructions, fragility warnings, and any special requirements for storage or transportation.

Logistics

Logistics plays a crucial role in ensuring that camera modules arrive at their destination on time and in good condition. Accidents in transit can be reduced through meticulous preparation of shipping routes, the use of reputable carriers, and real-time tracking of shipments. It is also important to use reliable shipping partners who have dealt with fragile electronics before.

Conclusion

Packing camera modules for shipping is an art that must be perfected to ensure the safe arrival of these priceless parts at their destinations. Camera modules contain sensitive technology that can be damaged by things like electrostatic discharge if they aren’t properly packaged. Manufacturers and shippers can guarantee that camera modules will arrive undamaged and ready to fuel innovation across a wide range of applications by using secure enclosures, anti-static measures, sealed packaging, a layered approach, and clear labeling. Proper packaging can make a huge difference in the delivery of outstanding service in today’s technologically advanced world. As our reliance on camera modules grows, so too must our ability to safely transport them so that they arrive in pristine condition, ready to record life as it happens.