CNC (computer numerical control) machining is the production process where the preprogrammed computer programs dictate the movement of factory machines. The method controls many complex machines, from lathers and grinders to CNC routers and mills. The CNC machining can do the three–dimensional cutting jobs in a single prompt set.

The preprogrammed software dictates the factory machinery and tools movement in CNC machining. The process supersedes the disadvantage of manual control and guiding machining tools commands through buttons, wheels, and levers. If you want to use CNC machining to manufacture different products, you must know how CNC programming and CNC machining work. You should also know about the critical types of CNC machinery and the type of work they can do.

How CNC machining works

After the system’s activation, desired cuts get prompted in the software, and the corresponding machinery and tools dictate them. They now carry out the specified dimensional tasks like a robot.

The code generator in this numerical system often assumes the mechanisms to be flawless despite higher risk errors when the CNC machine gets commands to cut in many directions simultaneously. The part program is a series of inputs that places a tool in any numerical control system.

Programming of CNC machining

In CNC production, numerical control operates the machines where the software gets designated to control the object. The G-code is the language that controls CNC machining written to gain complete control of the different behaviors of that machine like feed rate, coordination, and speed.

CNC machining enables the preprogramming of position and speed of machine tool tasks and runs them through the software in predictable and repetitive cycles. They do all these with little human operators’ involvement.

In CNC machining, a 3D or 2D CAD drawing gets conceived and later translated into computer codes that CNC has to execute. After inputting the program, operators give a trial to make sure there aren’t any mistakes in the coding.

Machining systems types

CNC machining is in all corners of the production sector. It’s also vital in the plastic and metal production areas. Here are the different CNC machining types.

Closed/Open-loop machining system

Position control gets determined via a closed-loop or open-loop system in CNC manufacturing. In the latter, signaling runs in one direction between a motor and a CNC controller. In the closed loop, a controller can receive feedback which can create errors corrections. The closed loop can rectify errors in position and velocity.

If the machining process speed and force are minimal, then they get done by the open-loop system. Anything else gets done by the closed-loop system to ensure consistency, accuracy, and speed needed for industrial applications like metalwork.

The different CNC machining types

The growth in technology has risen the use of CNC machining at the expense of the old motors. The common CNC processes are hole punching, laser cutting, and ultrasonic welding.

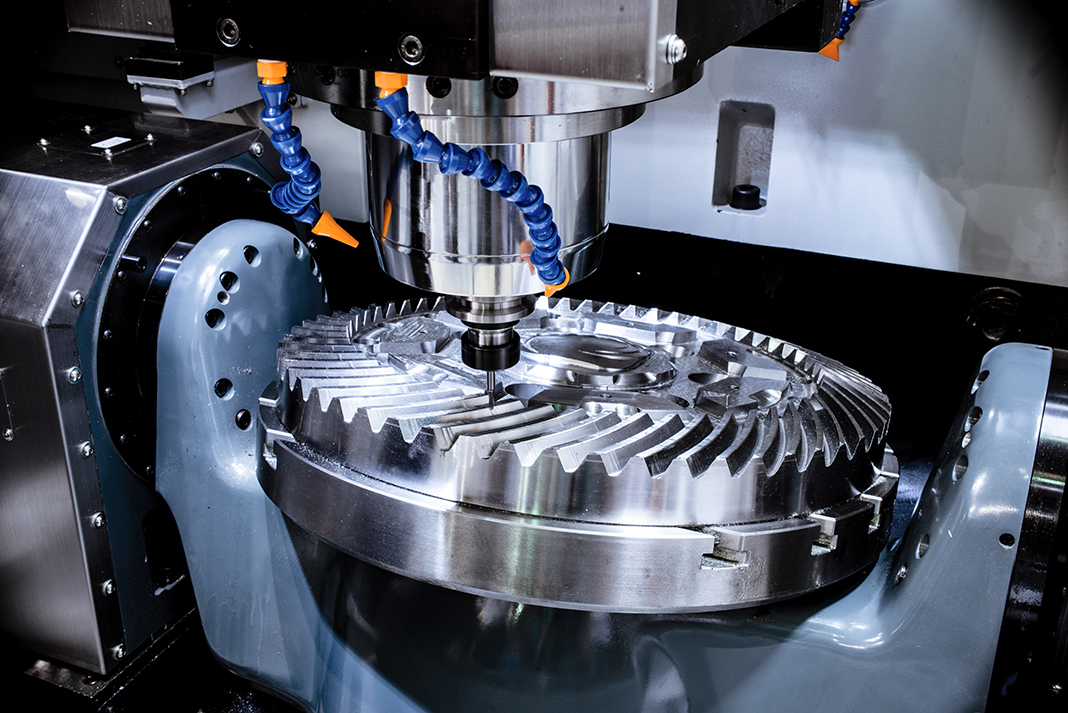

CNC mills

Run-on programs comprise letter and number-based prompts to guide pieces across different distances. Primary mills have three-axis systems (X, Y, and Z), but the recent ones can have three more axes.

Lathes

They give complex designs that are impossible using manual-run machine versions. Control functions of lathes and CNC-run mills are similar.

Plasma cutters

A plasma torch aids in cutting the material. The process gets used on metals but can also work on other surfaces. To give heat and speed needed in cutting the material, the generation of plasma is through electrical arcs and compressed air gas combination.

The other CNC machining types are electric discharge machines and water jet cutters.

Conclusion

To improvise your manufacturing process, use the latest technology of CNC machining. You will get the exceptional value of your products to increase your market and income.